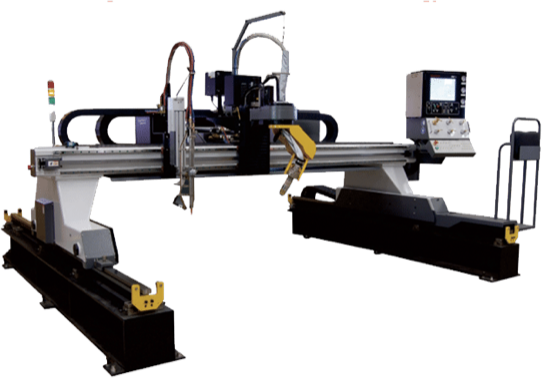

Athlete

High-speed precision CNC cutting machine ideally suited for High Definition Plasma. This modular machine is easy to relocate and saves floor space without sacrificing quality.

The Details & Features:

- All-in-one compact design including gantry, fume collection duct and table

- MicroEdge Pro controller

- Precision rack & pinion dual drive

- Double linear way in transverse & longitudinal axis

- High-efficiency sequential zone fume collection table ready for use

- For 1 plasma only (high definition plasma power supply recommended)

- Easy installation & minimum setup time