The Complete Guide to Oxy-Acetylene Torches: Setup, Safety & Pro Tips

Whether you’re fixing a trailer in your garage, teaching your first trade school class, or running a full fabrication shop, an oxy-acetylene torch is one tool every metalworker should know inside and out.This guide covers everything: how an oxy-acetylene torch works, what’s inside a full acetylene torch kit, how to handle oxy-acetylene cutting like a pro, step-by-step oxy-acetylene setup, safety and troubleshooting tips to keep your torch running like new.

What Is an Oxy-Acetylene Torch, and Why It’s Still a Shop Essential

An oxy-acetylene torch combines pure oxygen and acetylene gas to create one of the hottest controllable flames used in metalworking, up to 6,000°F. That extreme heat lets you:

- Cut through thick steel cleanly

- Weld or braze metal joints

- Heat seized parts for removal or forming

Here’s the basic idea:

- Oxygen and acetylene gases are stored in separate cylinders.

- Regulators control gas flow to safe working pressures.

- The two gases mix inside the torch handle and ignite at the tip.

- Adjusting the oxygen and acetylene valves fine-tunes the flame.

When you press the lever on a cutting torch, a jet of high-pressure oxygen blows away the molten steel; that’s what we call oxy-acetylene cutting.

It’s old-school tech that’s still highly relevant. While plasma and laser cutters are popular, you can’t beat oxy-acetylene for portability, affordability, and field repairs.

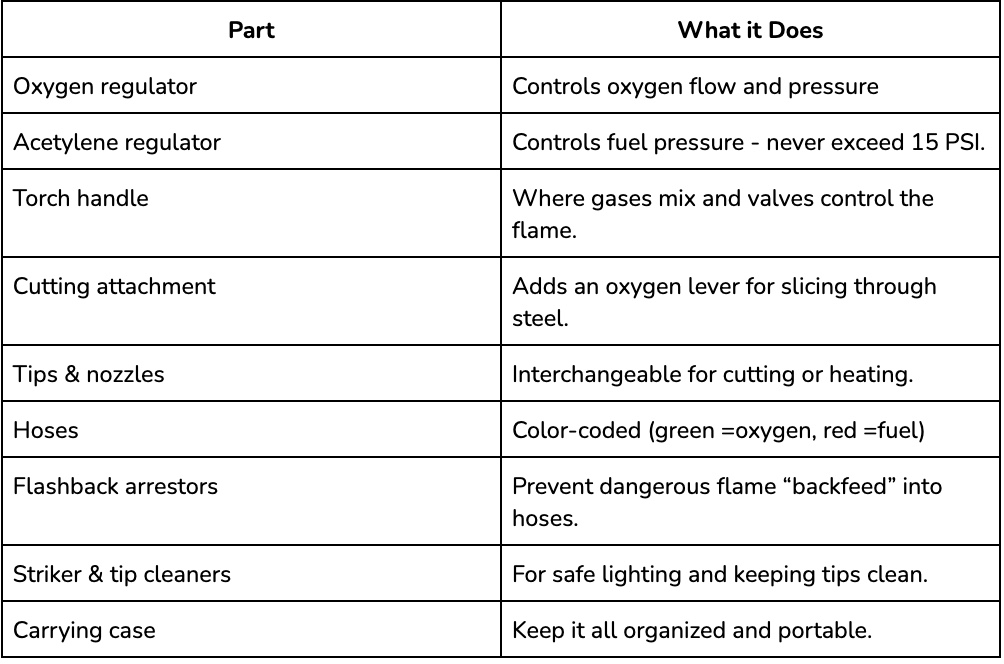

What’s Inside an Oxy-Acetylene Torch Kit?

If you’re shopping for your first acetylene torch kit, knowing what you’re getting (and what each part does) makes setup a lot easier.Here’s what a typical oxy-acetylene kit includes:

Shop the Best Oxy-Acetylene Torch Kits

Ready to get set up? These popular options from Arc Solutions offer reliable performance and quality components for both DIY and pro shops:

- Victor Medalist Classic Outfit — the go-to medium-duty torch for welding and cutting up to 5”.

- Victor Medalist 250 Cutting Outfit — perfect for shop or field use, complete with regulators and torch handle.

- Harris Ironworker Deluxe Kit — heavy-duty performance for industrial and fabrication shops.

Each one includes the essentials for both oxy-acetylene cutting and welding, just add cylinders and you’re ready to roll.

Oxy-Acetylene Cutting vs Other Methods: When to Use Each

Wondering when to grab your torch instead of the plasma cutter? Here’s the quick breakdown.

When Oxy-Acetylene Cutting Wins

- Steel only: It’s unbeatable for ferrous metals, clean, controlled, and cost-effective.

- Field work: No need for electricity, just gas.

- Thick plate repairs: Works great for dismantling or shaping heavy steel.

- Heating & bending: Great for removing bolts or preheating weld zones.

When It’s Not Ideal

- Aluminum or stainless: Those metals don’t oxidize properly, thus, plasma is better.

- CNC production: Laser or plasma gives cleaner edges at higher speeds. On plates 2” thick or less, although oxy fuel is a much less expensive option.

- Tight precision: Oxy-acetylene can have a wider kerf (cut width).

Bottom line: Oxy-acetylene cutting is still a must-have for mobile repairs, fabrication, and general shop work.

Step-by-Step: Oxy-Acetylene Setup for Beginners

Setting up an oxy-acetylene torch might look intimidating, but once you’ve done it a few times, it’s second nature.

Here’s how to safely set up your kit:

1. Secure Your Cylinders

Keep them upright and chained to a cart or wall. Never lay acetylene tanks flat.

2. Check for Clean Fittings

Crack open (quickly open/close) each cylinder valve before attaching regulators — this blows out dust or dirt.

3. Attach Regulators

- Oxygen to oxygen

- Acetylene to acetylene

- Tighten with a proper wrench, no pliers.

4. Connect Hoses

Green hose = oxygen, red hose = acetylene. Match threads (acetylene uses left-hand threads).

5. Open Valves Slowly

Open the oxygen tank valve fully. Open acetylene only one full turn.

6. Set Regulator Pressures

Typical starting pressures:

- Oxygen: 5–10 PSI

- Acetylene: 5–7 PSI

(Always check the tip chart from your kit.)

7. Purge the Lines

Briefly open each torch valve (one at a time) to purge air.

8. Light the Torch

- Open the acetylene valve slightly and ignite with a striker.

- Slowly open the oxygen valve until you see a tight, blue neutral flame.

9. Start Cutting

Use the preheat flames to bring the metal to cherry red, then press the cutting oxygen lever to start slicing.

Oxy-Acetylene Torch Safety Checklist

Using an oxy-acetylene torch safely is non-negotiable. A few mistakes here can get dangerous fast.

Before You Light

- Inspect hoses, regulators, and tips for leaks or cracks.

- Use soapy water to check for gas leaks — never a flame.

- Confirm flashback arrestors are installed.

- Clear the work area of rags, oil, and flammables.

During Use

- Never exceed 15 PSI on acetylene — it becomes unstable above that.

- Keep the torch tip clean.

- Don’t cut near sealed containers or tanks.

- Use the proper shade goggles (Shade #5–6).

After You’re Done

- Close cylinder valves first, then release torch valves to bleed lines.

- Loosen regulator screws to relieve spring tension.

- Coil hoses neatly and store the kit in a dry spot.

- Ensure you have a “Fire Watch” as molten metal may bounce off hard surfaces

Storing it right not only keeps you safe, it extends the life of your oxy-acetylene setup, too.

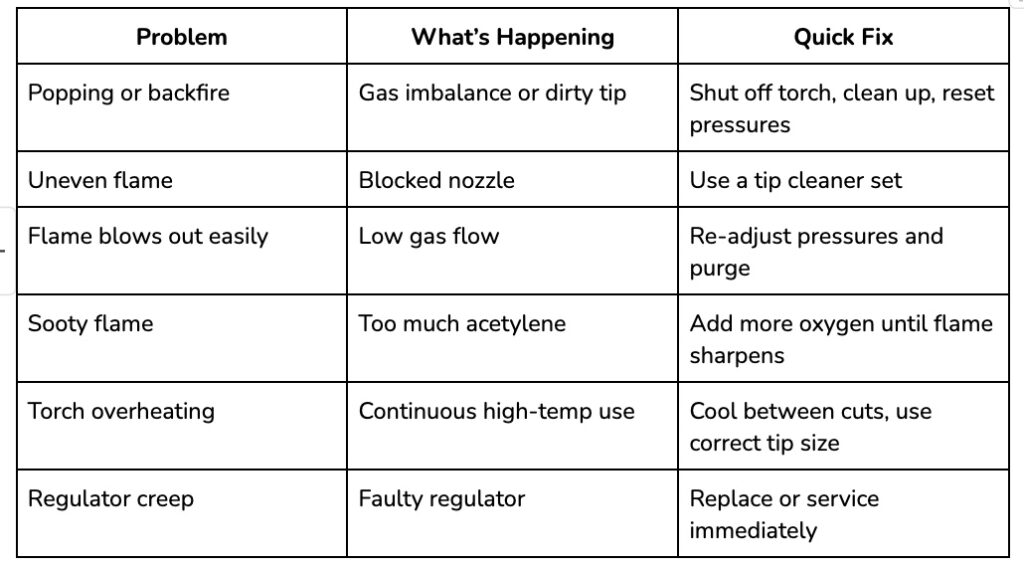

Common Oxy-Acetylene Torch Problems (and Fixes)

Every welder eventually runs into these issues. Here’s how to troubleshoot them:

Pro tip: Keep a tip cleaner kit in your toolbox — it’s cheap insurance against frustrating flame issues.

Maintenance Tips to Extend Torch Life

Want your gear to last? Here’s what pros swear by:

- Always purge lines before and after use.

- Keep torch tips clean — even a minor clog can throw off the flame.

- Store hoses are loosely coiled (no sharp bends).

- Cap regulators when not in use.

- Keep spare O-rings and cleaning tools in your kit.

- Wipe down your torch body regularly to prevent grit build-up.

If you’re using your torch daily, schedule a full inspection every few months; regulators and valves wear with time.

Why Every Welder Still Needs an Oxy-Acetylene Torch

Sure, plasma and laser cutting tech are awesome, but an oxy-acetylene torch is versatile, mobile, and timeless. From farm repairs to custom fabrication, it’s the Swiss Army knife of metalwork.

If you’re just getting started, grab a complete acetylene torch kit from Arc Solutions. You’ll have everything you need for cutting, welding, and heating in one box, plus reliable gear that’ll last for years. Shop our top-rated torch kits from Arc Solutions!

Final Thoughts

An oxy-acetylene torch isn’t just another shop tool; it’s a workhorse that’s powered metalworking for more than a century. Whether you’re a DIY metalworker, professional welder, fabrication shop manager, or trade school student, understanding your oxy-acetylene setup is a skill you’ll use for life.

Take the time to learn the setup, respect the safety rules, and invest in quality equipment. Your cuts will be cleaner, your welds smoother, and your torch will last for years of reliable service.

Back to blog