Hypertherm Powermax 30 XP vs 45 XP: Which is Right for Your Workshop?

Known for its portability, user-friendly controls, and reliable plasma arc, the Hypertherm Powermax series boasts some of the most reputable plasma cutters on the market. Whether you're new to cutting or a pro, these tools cover a wide range of applications, making them a great choice for anyone.

Which Plasma Cutter is Best for you?

Two of the most popular models are the Hypertherm Powermax30 XP and the Hypertherm Powermax45 XP. This selection of machines caters to a wide range of metal fabrication needs, from cutting thinner metal projects to gouging tasks.

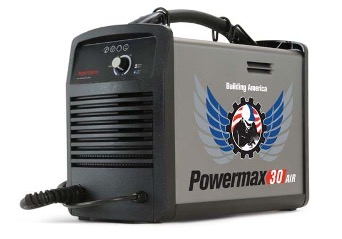

Powermax30 XP

The Powermax30 XP has a host of impressive capabilities for being the less formidable of the two machines. The 30XP has a recommended cut capacity of 3/8in (10mm), a severance cut capacity of 5/8in (16mm), and an output amperage of 15-30 A. This machine supports drag cutting, fine feature cutting, and extended reach cutting or gouging. The 30XP also comes in a carrying case that includes:

- 240 V/20 A plug with adapters or 120 V/15 A and 240 V/20 A circuits

- Hypertherm Powermax 30 XP Power supply, 15 ft. (4.5 m) Duramax LT hand torch with standard consumables, 15 ft. (4.5 m) work clamp

- Operator and safety manuals

- Consumable kit with 1 standard nozzle, 1 electrode, 1 Fine Cut nozzle, and 1 Fine Cut deflector

- Carrying strap

- Leather gloves

- Shade 5 glasses

Fully loaded with all these items, the Powermax30 XP is a good choice as an on-the-go plasma cutter. The machine by itself weighs in at about 21lbs, making it one of the lightest plasma cutters Hypertherm has to offer. Along with its lightweight, the Powermax30 XP also offers dual voltage 120V/240V, thus enhancing its portability to plug in anywhere.

On mild steel cutting 1/8 in thickness, the Powermax30 XP outperforms traditional oxy-fuel cutting speed by over 300%. The enhanced speed of plasma cutting saves the end user both time and money. Not only is this machine fast, but as mentioned above, it allows FineCut® capabilities making it a good choice for fine-detailed and thin-metal projects. The Powermax30 XP stands out as a competitor in the realm of plasma cutters by showcasing its versatility, not only excelling at primary functions but also demonstrating the capability to gouge metal effectively. For a hobbyist or someone who plasma cuts on the go consistently or enjoys being a garage hobbyist, the Powermax30 XP is a great investment.

Powermax45 XP

As the more robust of the two machines, the Powermax45 XP is capable of everything the Powermax30 XP can do and more. This machine supports:

- Drag cutting

- Extended reach cutting and gouging

- Fine feature cutting

- Flush cutting

- Max control gouging

- Marking

- Mechanized cutting

- Precision gouging

This comprehensive list of functionalities demands a heightened level of performance from the machine. The Powermax45 XP has a recommended cut capacity of 5/8in (16mm), a severance cut capacity of 1-1/8in (29mm), and an output amperage of 10-45 A. This machine is also lightweight at 30 lbs and comes with a lift handle on top. However, it does not offer the ability to plug into a 120V household outlet like a Powermax30 XP and is an overall larger machine dimensionally. But don’t let this detract from all the other attractive features the Powermax45 XP hosts. The Powermax45 XP is a high-performing plasma cutter with industrial capabilities and is often used as such. The unit would typically be considered overqualified to be purchased as solely a garage hobby cutter.

This machine offers compatibility with hand torches, machine torches, robotic torches, and handheld long torches. The Powermax45 XP torches are also equipped with FastConnect™ torch to allow for quick and easy switching between torches. Hypertherm also offers a cartridge adapter that allows the torches that are compatible with the Powermax45 XP to accept the new SYNC cartridges. The SYNC cartridges are an added convenience in plasma cutting because they eliminate the need for multiple consumable pieces. Instead of having an individual swirl ring, electrode, nozzle, shield, and retaining cap, with the cartridge adapter (428951) the SYNC cartridge functions as a 5-in-1.

Choosing your Hypertherm Plasma Cutter: Expert Guidance

In conclusion, the Hypertherm Powermax series stands as a pinnacle in the realm of plasma cutters, catering to diverse metal fabrication needs. On one hand, The Powermax30 XP, with its lightweight design and versatile capabilities, is an excellent choice for on-the-go plasma cutting tasks, boasting remarkable speed and precision. On the other hand, the Powermax45 XP offers industrial-grade performance, featuring an extensive range of functionalities and compatibility with various torch types, including the innovative SYNC cartridges for added convenience. Whether you're a hobbyist or an industrial professional, the Powermax series delivers cutting-edge technology and unparalleled performance for all your metalworking needs.

Are you ready to enhance your workshop's cutting efficiency? Decision-making can be challenging, but with the right information, it becomes simpler. Whether your interest is piqued by the compact precision of the Powermax 30 XP or the powerful versatility of the Powermax 45 XP, the ideal plasma cutter for your needs is within reach. Get in touch with us now for expert guidance tailored to your specific requirements, or explore our detailed product listings to make an informed decision. The perfect Hypertherm model for your workshop is just a step away – let's make that choice together today!

Back to blog