You’re Searching for a Welding Boom for Sale, Now What?

Choosing the right equipment is critical to success when optimizing your shop’s efficiency and quality. In manufacturing industries specializing in heavy fabrication, a welding boom system is one of the most significant investments you can make. Read on to determine if a boom is right for you.

Welding Boom Parameters

When beginning your research into welding booms, it’s important to evaluate your needs and preferences upfront. This will streamline the buying process and help you make the best choice.

We’ve compiled some questions to ask yourself to help narrow down exactly what you’re on the hunt for in your next welding boom.

What Space Do You Have Available?

Consider the size of your shop and how the boom system will fit into the available space. Arc Solutions offers customizable options to ensure your boom integrates seamlessly into your workspace.

What Types of Welding Do You Perform Most?

Different boom systems may be better suited to specific welding processes, so choosing one that matches your shop’s primary activities is important. Some of the best welding and Swivel Arc boom combinations are with MIG welding, especially when it comes to aluminum MIG welding.

What is Your Preferred Reach and Range of Motion?

Evaluate the boom’s reach and flexibility to ensure it can cover all necessary areas of your workspace without frequent adjustments. Keep in mind that the welding gun will add additional reach to what the boom arm provides.

What Durability and Level of Maintenance Are You Looking For?

Look for a welding boom system built to withstand the demands of your shop. Durable construction and easy maintenance are key to ensuring a long-lasting investment. When doing MIG welding, the wire delivery equipment must be designed properly to prevent problematic feeding issues.

Benefits of Welding Boom Arms

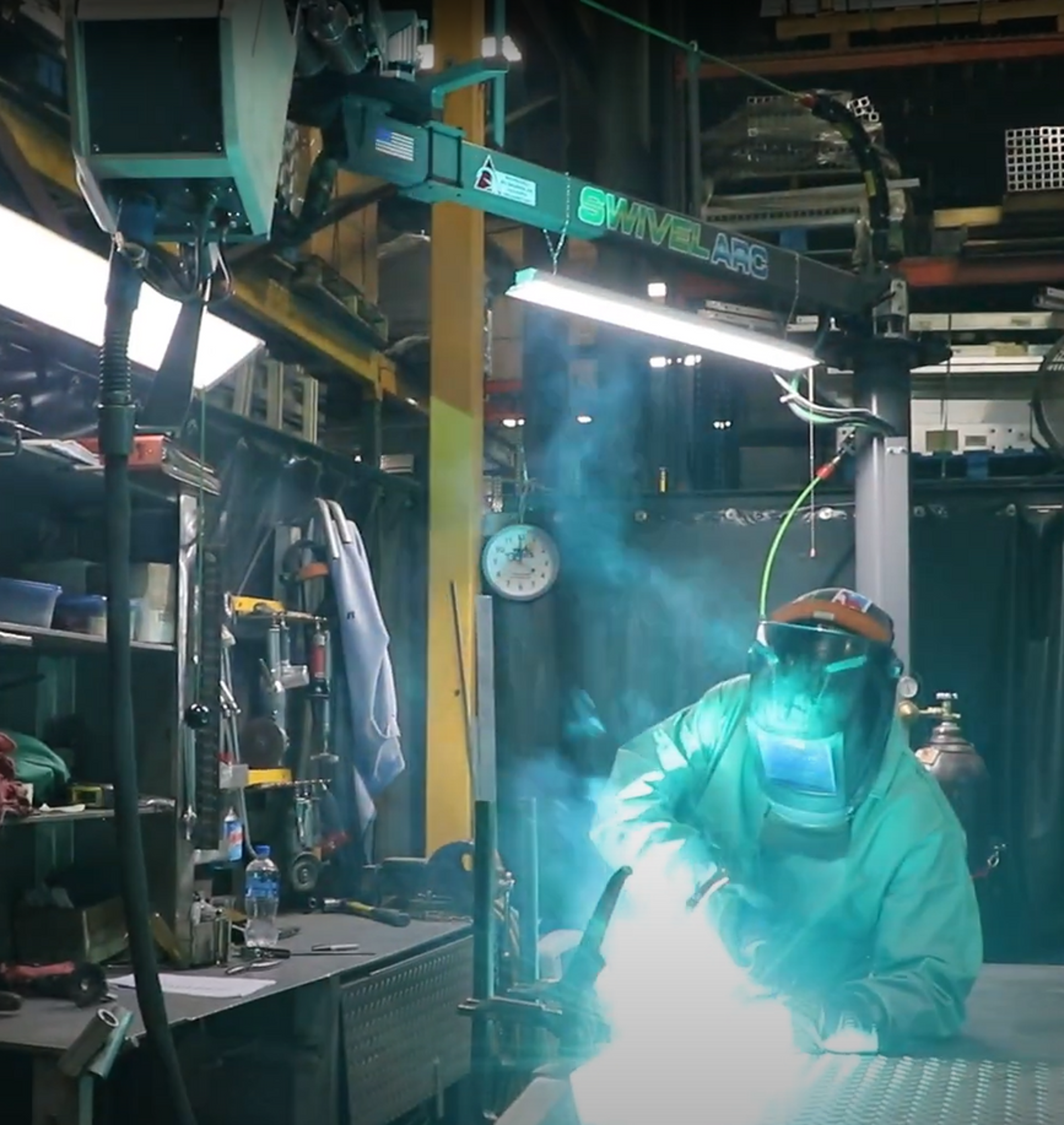

A welding boom system, like our Swivel Arc, offers a host of benefits that can revolutionize the way a shop operates:

Enhanced Accessibility

Welding booms provide a flexible reach, allowing welders to access hard-to-reach areas without moving heavy equipment. This saves time and reduces the physical strain on workers, leading to increased productivity. Swivel Arc booms come in 12ft, 15ft, and 20ft lengths to suit any shop layout, ensuring you have the reach necessary for every task. The Swivel Arc boom has 270 degrees of rotation in the primary arm, allowing welds to be placed in nearly any position.

Improved Safety

Welding booms significantly reduce tripping hazards by keeping cables, torches, and other equipment off the floor. This creates a safer work environment and minimizes the risk of accidents.

Space Efficiency

Welding booms help you maximize your shop floor space by keeping tools organized and out of the way. This streamlined setup allows for more efficient workflow and better use of available space.

Swivel Arc booms come with several different mounting options depending on their location within the shop setting. Stationary options include column mounts and pedestal mounts, and a portable option allows a pedestal-mounted boom to be placed on a base that can be easily moved with a forklift.

Consistent Quality

A stable, easily maneuverable boom system ensures that welders can perform their tasks with precision, leading to consistent, high-quality results. This consistency is vital for maintaining product standards and meeting customer expectations. The booms can push 3/64” aluminum 33ft without feeding issues. The wire will not bird nest in the wire feeder and it can be used with aluminum, stainless steel, Inconel, silicon bronze, and more.

Versatility

Swivel Arc booms can convert existing power sources and feeders for boom applications, providing versatile solutions for various needs. While aluminum applications have stricter equipment requirements, our system effectively accommodates them. Additionally, dual feeder options are available to enhance functionality and efficiency.

Swivel Arc Additional Features

Arc Solutions’ Swivel Arc welding booms are designed with the modern welding shop in mind. Here’s what sets them apart:

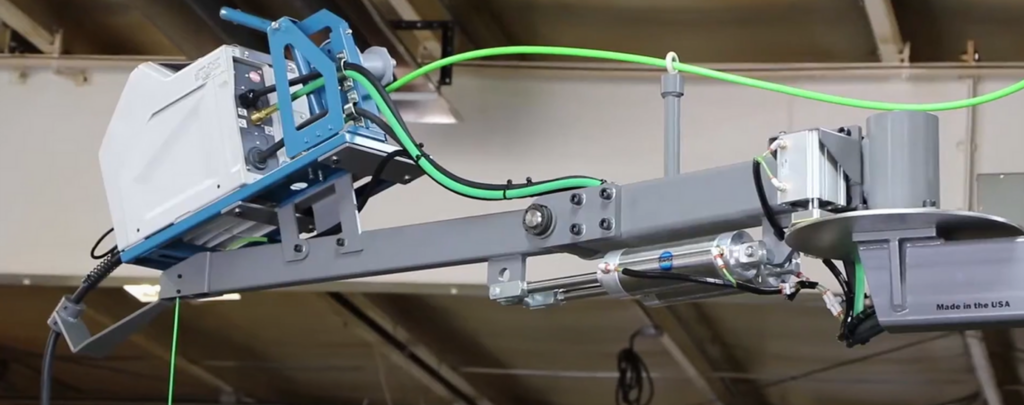

- 270-Degree Rotation on the Primary Arm: With the vast swing of the primary arm, in addition to the added flexibility of the secondary arm, there is virtually nothing inside the boom arc that can’t be reached.

- Heavy-Duty Construction: Built from high-quality materials, the Swivel Arc is engineered to withstand the toughest industrial environments and deliver reliable performance year after year. The tapered bearings allow a fine-tuned adjustment of the force required to rotate the boom.

- Ease of Use: With intuitive controls and smooth operation, the Swivel Arc simplifies the welding process, allowing your team to focus on quality work.

- Air Brakes and Feed Assist: Swivel Arc booms can be equipped with air brakes for each rotating joint to easily adjust the work position. Another optional accessory is the pneumatic feed assist, which delivers the wire to the back of the feeder at zero pounds of draw.

Elevate Your Shop Efficiency

Maximize your shop’s efficiency, safety, and productivity with the Swivel Arc welding boom system from Arc Solutions. Tailored to meet your unique needs, our welding booms offer long-term performance and reliability.

Trust Arc Solutions to equip your shop with the tools you need for lasting success. Contact our team to learn more about our boom systems and feel confident in your investment.

Back to blog