Welding Tables: How to Choose the Right Setup

At Arc Solutions, we understand that choosing the right welding table is key to a productive and efficient workspace. Whether you’re a home welder, fabrication shop owner, or industrial professional, selecting the right table ensures precision, durability, and ergonomic comfort.

Fixed vs. Portable Welding Tables

One of the first decisions when selecting a welding table is whether to go for a fixed or a portable setup. Fixed welding tables are ideal for larger workshops and industrial settings. They provide a stable, durable surface that can handle heavy loads and frequent use. These tables often come in steel construction and feature pre-drilled holes for clamping and fixturing, making them perfect for repeatable fabrication tasks.

On the other hand, a portable welding table is excellent for home welders or smaller workshops where space is limited. These tables are designed for mobility without sacrificing stability. Many portable models feature folding legs, adjustable height, and modular surfaces, so you can customize them for a variety of projects.

Material Considerations: Why Steel Welding Tables Matter

The material of your welding table plays a critical role in durability, accuracy, and long-term performance. Steel welding tables are the industry standard, and the only option we offer, because they provide the strength and precision required for professional welding environments. Steel delivers an exceptionally stable surface, withstands high heat without degradation, and resists warping over time, even under heavy use.

Our steel welding tables, including portable options, are engineered to support demanding workflows while maintaining accuracy. Many feature precision grid or T-slot layouts that allow for repeatable clamping, fixturing, and alignment, helping welders work faster and more consistently. Even when used for aluminum welding applications, a steel table provides the rigidity and reliability needed to achieve clean, precise results.

Size Matters: Choosing the Right Dimensions

Choosing the correct size of your welding table is just as important as the material. Consider both the height and surface area to ensure comfort and efficiency during long welding sessions. A welding workbench that is too small can restrict movement and limit project complexity, while an overly large table may take up unnecessary space and can be harder to manage.

For home welders, a compact table around 36″ x 24″ may suffice, while fabrication shops often require tables exceeding 60″ in length for large assemblies. Adjustable welding tables provide the flexibility to fine-tune the height for different projects, reducing strain and improving precision.

Customization Options: Clamps, Fixtures, and Grid Layouts

Modern welding tables are designed with customization in mind. Look for tables that offer clamps, fixtures, and grid layouts. These features allow you to secure your workpieces in precise positions, ensuring accurate welds and consistent results.

Grid layouts, especially those with T-slots, enable you to attach clamps and accessories in various configurations. This is invaluable for both repetitive tasks and unique projects. For more on optimizing your welding setup, explore our welding accessories page.

Maintaining a Flat, Durable Surface

A flat surface is crucial for accurate welding. Over time, tables can warp or become scratched, which impacts the quality of your work. To maintain a durable surface:

- Regularly inspect and clean your table to remove slag, debris, and rust.

- Protect your table’s surface by using sacrificial plates or other coverings when doing heavy work.

- Keep your table level—use a level to check it regularly, especially for precision tasks.

Maintaining a well-kept surface extends the life of your table and improves the quality of every project.

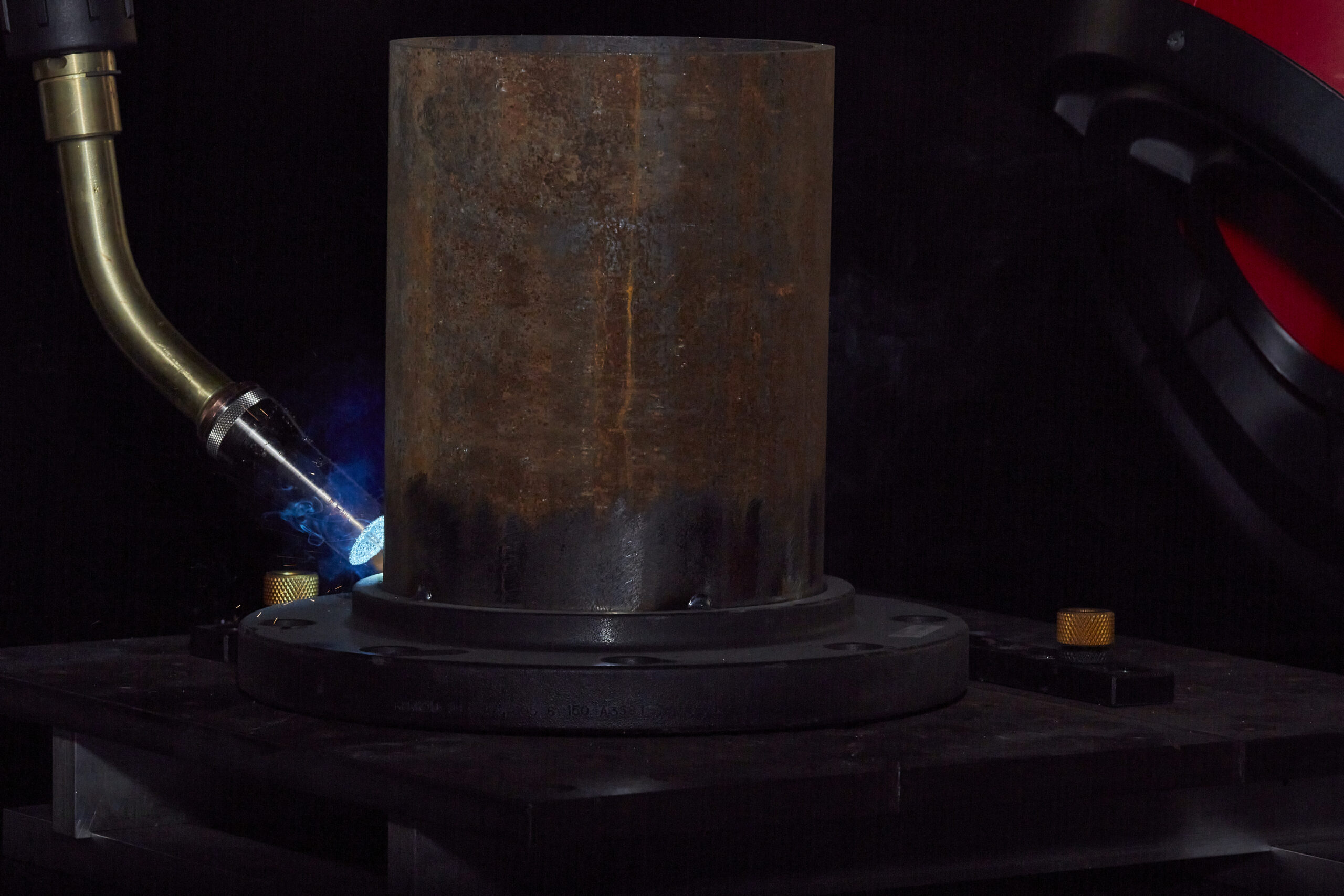

Setup Examples

- Example 1: Home Workshop Setup A compact, portable welding table with adjustable height, a small T-slot grid, and clamps for securing small projects. This setup is perfect for hobbyists working on metal art or home repair tasks.

- Example 2: Fabrication Shop Setup A large steel welding table with integrated T-slots, a wide surface area, and a selection of fixturing clamps. Ideal for repetitive, precision welding tasks such as structural steel assemblies.

- Example 3: Industrial Welding Setup A fixed steel welding workbench with a modular grid system, overhead lighting, and adjustable fixtures. Designed for high-volume production and heavy-duty applications.

Quick Tips for Choosing the Right Welding Table

- Assess your workspace – Measure the area available and ensure your table fits comfortably.

- Determine the type of projects – Large assemblies may require a fixed steel table, while smaller projects can be managed on a portable welding table.

- Consider adjustability – Adjustable welding tables allow for ergonomic working conditions and can accommodate a variety of tasks.

- Think about customization – Look for tables with T-slots or modular grid systems for flexibility.

- Maintenance matters – consistent cleaning and inspections ensure your table stays dependable and ready for years of use.

Why Investing in the Right Welding Table Matters

The right welding table impacts not only your comfort and safety but also the quality of your work. A well-designed steel welding table offers precision, durability, and adaptability for a variety of projects. Whether you opt for a portable welding table for flexibility or a fixed welding workbench for heavy-duty tasks, investing in a quality setup can boost your productivity and skill development.

At Arc Solutions, we provide welding tables and accessories designed to help you build the perfect workspace. Set up your workspace for success, find durable, ergonomic welding tables designed for both precision and power. Explore our full range of welding tables and accessories today.

Back to blog