Welding in the Heat: Summer Maintenance Tips for Your Machines

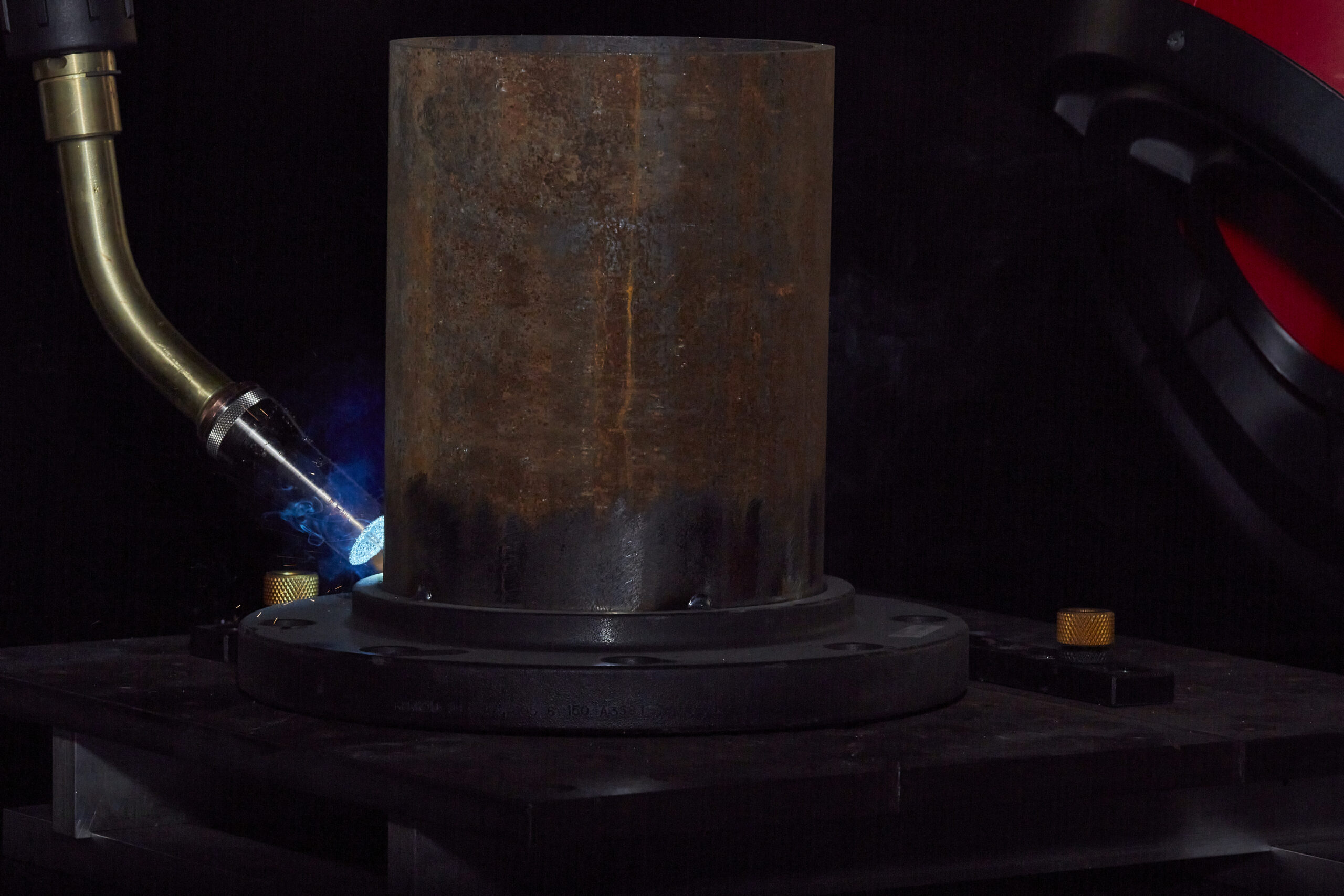

When summer temperatures rise, so does the strain on your equipment. For field welders, contractors, and shop foremen, the heat is not just uncomfortable. It is a serious threat to welding machines. From overheating risks to the accumulation of dust and moisture, summer conditions can shorten the life of your equipment and slow down your projects.

At Arc Solutions, we know that a few preventative steps can make all the difference. Let’s explore how you can protect your welding equipment this summer and keep downtime to a minimum.

Why Summer Conditions Are Hard on Welding Equipment

Welding in high heat brings unique challenges that go beyond basic discomfort. The extreme environment causes your machines to work harder, and failure to adapt your maintenance routine can lead to expensive breakdowns.

Common Summer-Related Welding Issues:

- Overheating: Machines generate a lot of heat on their own. When combined with 90+ degree weather, issues can quickly arise.

- Dust and debris: Increased use of fans and open workspaces leads to more airborne particles clogging filters and internal components.

- Humidity and condensation: Moisture can damage circuit boards, lead to corrosion, or cause erratic machine behavior.

- Extended usage: Summer months are often peak project season, which means less rest time for machines and more wear and tear.

- UV exposure: Prolonged exposure to direct sunlight can degrade plastic housings, wiring insulation, and protective casings.

How Summer Affects Welding Quality

Beyond equipment failure, heat can also affect weld quality. Materials may expand in hot conditions, leading to inaccurate welds. Higher ambient temperatures can change gas flow dynamics, which impacts shielding and penetration. If your machine is overheating, it may reduce arc stability or lead to inconsistent wire feeding. All of these factors can compromise the structural integrity of your welds.

Additionally, elevated humidity can affect consumables like wire and rods, making them less reliable. Flux can absorb moisture from the air, increasing the likelihood of porosity in your welds. Without tight control over your work environment, even skilled welders may see lower quality outcomes during the summer months.

Summer Welding Tips to Prevent Downtime

Proactive maintenance is always more affordable than emergency repairs. These summer-specific tips will help keep your machines in working condition and protect your investment. You can also learn detailed Lincoln Electric maintenance practices in our comprehensive Lincoln Electric welder maintenance article.

1. Schedule a Mid-Year Service Check

Before you dive into back-to-back summer projects, it is wise to book a professional maintenance check. Arc Solutions offers seasonal service appointments that evaluate machine performance, replace worn parts, and clean critical components. Book your summer service check now to avoid breakdowns when the heat is on.

2. Clean and Replace Filters Often (Engine-Drive Welders)

Airborne particles increase during the summer due to dry conditions, outdoor workspaces, and increased ventilation. Filters should be checked biweekly or after every major job, depending on your environment. See our welding repair parts. Recommended maintenance includes:

- Inspect filters

- Clean or replace engine filters as needed

- Check for signs of blockage or restricted airflow

Arc Solutions offers a variety of machine accessories and protective covers designed to help protect your equipment from tough environmental conditions. Check with your Arc Solutions representative for the latest options.

3. Keep Machines Out of Direct Sunlight

Heat buildup accelerates internal component failure. When storing your welder, keep it under shade, a tarp, or a fire-resistant cover. Here are some of the best practices:

- Store equipment in climate-controlled or shaded areas

- Avoid leaving machines in vehicles or open trailers in direct sunlight if possible

4. Adjust Work Timing When Possible

If your schedule allows, shift some of your heaviest welding tasks to earlier in the morning or later in the evening when outdoor temperatures are lower. This will reduce stress on the machine and prevent overheating.

Bonus Tip: If working indoors, ensure ventilation systems are optimized to push hot air out and draw cooler air in.

5. Monitor Duty Cycles Closely

Summer jobs often stretch beyond the standard duty cycle of your machine. If a welder is rated for a 60 percent duty cycle at 300 amps, exceeding that under high temperatures can cause serious damage. Here is what you can do to mitigate negative results:

- Know your machine’s duty cycle and operate within limits

- Let machines rest during peak heat hours

- Use external fans to assist in cooling

6. Store Consumables Properly

Hot, humid conditions can ruin consumables quickly. Always store rods, wire, and flux in dry, temperature-controlled containers. Consider using dehumidifiers or silica gel packs in your storage bins.

7. Inspect Leads and Cables More Frequently

Cables exposed to sunlight or lying on hot surfaces can develop cracks in insulation, become brittle, or fail unexpectedly. Inspection tips include:

- Look for discoloration, warping, or exposed wire

- Replace damaged leads promptly

- Use protective sleeves for added insulation

Summer Welding Maintenance Checklist

Use this checklist to keep your maintenance on track all summer long. Post it in your trailer, shop wall, or tool truck for quick access.

Weekly Maintenance Tasks

- Inspect air intake and exhaust vents for blockage

- Clean or replace filters

- Wipe down exterior surfaces

- Inspect cable connections for heat damage

- Check cooling fans for debris

Monthly Maintenance Tasks

- Clean circuit board compartments using compressed air or a vacuum

- Test for electrical continuity and grounding issues

- Review duty cycle performance against recent workloads

- Tighten any loose fasteners or mounting hardware

- Check for software or firmware updates if applicable

Before Each Job

- Perform a quick visual inspection of the machine and its leads

- Confirm fan operation and unrestricted airflow

- Check shielding gas lines and regulators for any leaks

- Ensure the machine is set up on a flat, shaded, and stable surface

Protecting Your Power Supply from Summer Stress

Your power supply is the heart of your welding setup, and it is especially vulnerable in extreme heat. Overloading the power supply in hot weather can cause thermal shutoff or permanent damage.

Tips to Protect Power Supply:

- Ensure cables are in good condition and not overheating

- Keep units cool with auxiliary fans or increased airflow

- Avoid exceeding duty cycles during peak heat hours, typically between 12 PM and 3 PM

- Use voltage surge protectors if thunderstorms are frequent in your region

- Consider rotating equipment if multiple machines are available. Rotating machines between jobs can keep them from overworking in one location.

Accessorize for the Season: Add-Ons That Prevent Problems

Simple accessories can make a big impact on summer performance. You can explore recommended add-ons on our machine accessories page. Whether you are working in the field or the shop, consider these seasonal add-ons.

Fans and Ventilation Enhancements

- Portable exhaust fans to increase airflow

- Clip-on fans for shop setups

- External fan kits to enhance internal cooling

Protective Covers

- Fire-resistant welder covers

- Heavy-duty tarps for on-site equipment

- Moisture-resistant storage bins for leads and torches

Cable and Hose Management

- Cable organizers to keep them off hot surfaces

- Insulated sleeves for high-heat protection

- Quick disconnects for faster maintenance

Do Not Let Heat Cost You: Schedule Service Now

The best way to beat the heat is to stay ahead of it. Arc Solutions offers comprehensive summer service checks for all major welding machines, including Lincoln Electric, Miller, ESAB, and others. We inspect for early signs of heat damage, replace vulnerable components, and ensure your machine is ready for the season ahead. Do not wait until you are stuck on the job with a damaged machine. Schedule a summer service with Arc Solutions today.

Why Partner with Arc Solutions?

At Arc Solutions, we do more than supply machines. We help you maximize performance and lifespan through fast, reliable welding machine repairs, preventative maintenance plans, access to quality replacement parts and accessories, and on-site or in-shop service options.

Our team works directly with field welders, contractors, and shop managers to keep operations running smoothly. We understand the realities of working in the heat and have the tools and expertise to help you stay productive.

Visit our services page to learn more about how we support working welders across industries.

FAQ: Summer Welding Maintenance

Q1: Why do welding machines overheat more in summer?

High ambient temperatures make it harder for welding machines to dissipate the heat they generate during operation. Combined with dust, humidity, and extended usage, this can cause internal components to run hotter, increasing the risk of overheating and machine failure.

Q2: What are the signs that my welding machine is overheating?

Common signs include the machine shutting off unexpectedly, decreased weld quality or arc instability, unusual smells or noises, and visible heat distortion or discoloration on machine parts and cables.

Q3: How can I extend the life of welding consumables in summer?

Store rods, wires, and flux in dry, temperature-controlled environments. Use sealed containers with moisture-absorbing packets and avoid leaving consumables exposed to heat or humidity.

Q4: When is the best time to schedule a summer service check?

Ideally, schedule your summer service before your peak project season begins, or at least mid-year. This proactive step helps catch issues early and keeps machines running smoothly during the hottest months.

Back to blog