Top Welding Safety Gear You Need

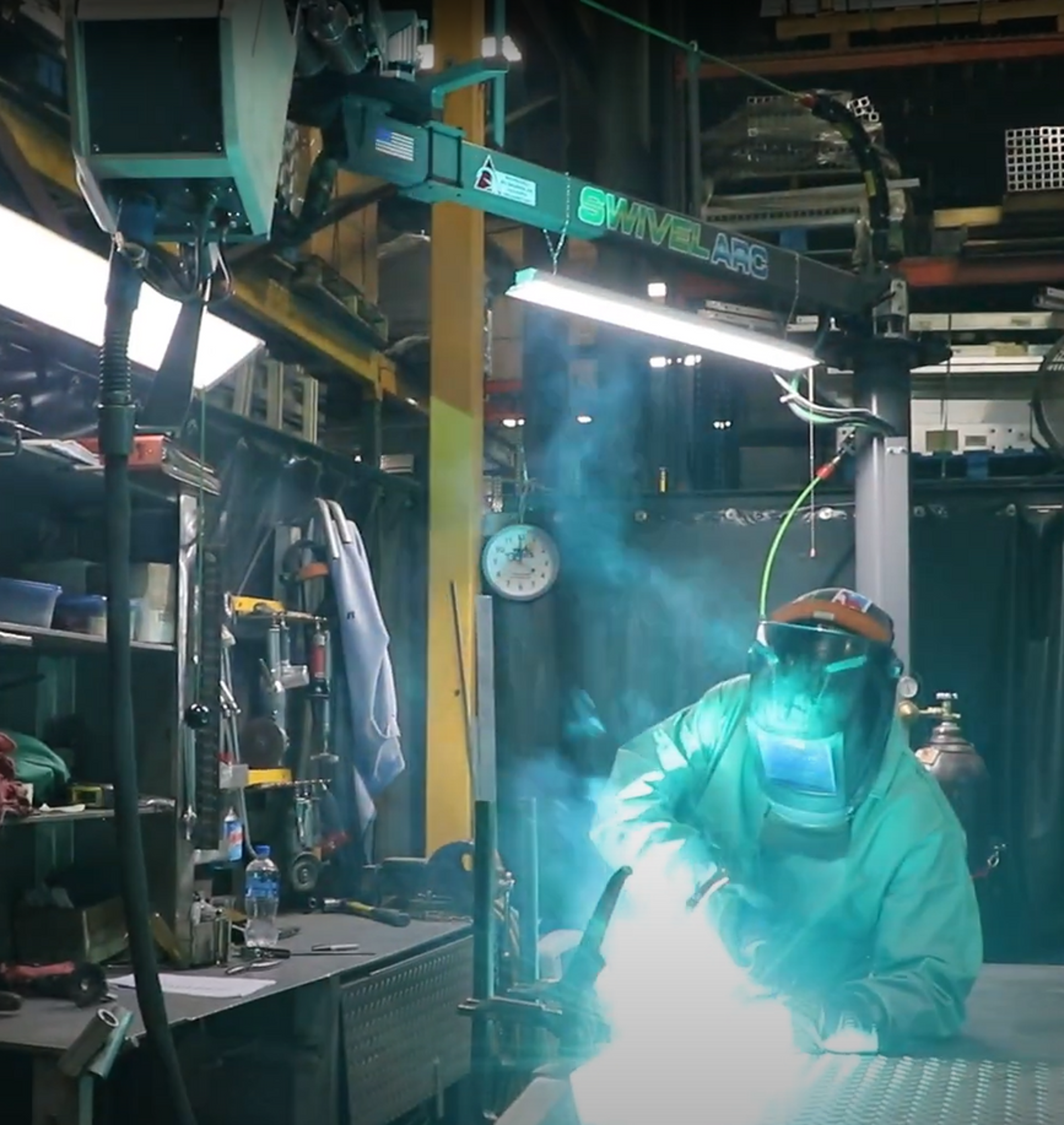

Welding is a skilled craft that comes with its fair share of risks. Whether you’re working in a professional fabrication shop or a home garage, having the right welding safety equipment is essential to protect yourself from sparks, heat, and harmful UV light. With so many options available, it can be challenging to know which gear is both reliable and effective.

Investing in the right welding safety gear isn’t just about following rules, it’s about protecting your health, enhancing comfort, and boosting confidence on every project. Whether you’re a professional fabricator or a weekend hobbyist, having high-quality welding protective equipment allows you to work more efficiently and safely.

A complete setup includes helmets, gloves, jackets, respirators, and accessories that together create a fully protected workspace. By staying up-to-date with the latest holiday welding gear as we head into 2026, you can ensure maximum safety while focusing on your craft with confidence.

Essential Welding Safety Equipment

A safe welding setup isn’t just about one piece of equipment, it’s about creating a complete system that keeps you protected and comfortable on every job. A reliable helmet and face shield are essential for guarding your eyes and skin from sparks, UV light, and heat, while sturdy gloves protect your hands during intense work. Flame-resistant jackets, sleeves, or full protective apparel add another layer of safety, and respiratory protection along with safety glasses helps shield you from fumes and airborne debris, especially during long sessions or when working with metals like stainless steel.

Even the small details make a big difference in welding safety. From welding magnets and fire-resistant blankets to keeping your workspace organized, each element plays a role in creating a safer, more efficient environment. When all of these pieces come together, welders can focus on their craft with confidence, knowing they’re fully equipped with the latest welding safety gear from Arc Solutions.

1. Welding Helmets

A welding helmet is the most critical piece of safety gear. It protects the eyes and face from sparks, UV/IR light, and intense glare.

Recommended Helmet:

- Lincoln 3350 ADV Auto-Darkening Helmets – Comfortable, durable, and perfect for professionals or hobbyists. Many come with free sleeves and gloves during holiday promotions.

Auto-darkening helmets provide additional convenience by adjusting shade levels automatically, which reduces neck strain and improves focus.

2. Welding Gloves

Welding gloves are key for protecting hands from heat, sparks, and sharp metal edges. The right pair of gloves allows welders to handle equipment safely without sacrificing dexterity.

Our Top Picks:

- Lincoln Electric MIG/TIG Gloves – Heat-resistant and flexible for precision work.

- Tillman Leather Gloves – Durable gloves suitable for high-intensity welding.

- Insulated Gloves – Great for cold environments or outdoor welding projects.

3. Welding Jackets and Apparel

Protective apparel shields the body from burns, sparks, and harmful UV exposure. Investing in a durable welding jacket, sleeves, or aprons is a must-have for anyone serious about safety.

Recommended Options:

- Lincoln Electric Welding Jackets – Flame-resistant and designed for heavy-duty work.

- Steiner Protective Sleeves – Flexible and comfortable for smaller tasks or lighter-duty welding.

- Protective Aprons – Ideal for high-temperature or long-duration welding jobs.

Well-designed apparel not only improves safety but also adds comfort, allowing welders to focus on precision and quality.

4. Eye and Respiratory Protection

Even with a helmet, additional eye and respiratory protection can enhance safety. This includes safety glasses, goggles, and respirators that protect against fine metal fumes.

Key Gear:

- Safety Glasses with Side Shields – Protect eyes from flying sparks or debris.

- Welding Respirators – Filter out harmful fumes, especially during prolonged welding sessions.

- Face Shields – Can be used alongside helmets for extra protection in cutting or grinding applications.

These items are critical for welders working with metals that emit dangerous fumes, such as stainless steel.

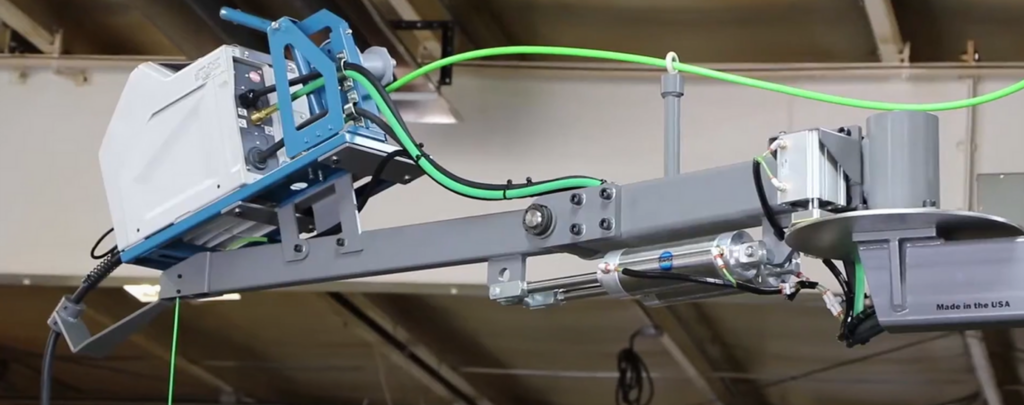

5. Accessories That Enhance Safety

Small but essential accessories often make a big difference in overall safety. Consider including these in your safety setup:

- Welding Magnets – Secure workpieces safely while keeping hands away from sparks.

- Fire-Resistant Blankets – Protect surrounding areas from stray sparks.

- Clamps and Tool Organizers – Help maintain a clean, organized workspace.

By pairing these accessories with your standard welding safety gear, you’ll create a safer, more efficient workspace.

Invest in Your Safety This Holiday Season

A complete welding safety setup keeps you protected, comfortable, and focused so you can do your best work. With the right gear, helmets, gloves, jackets, respirators, and more, you can tackle every project with greater confidence, efficiency, and peace of mind.

Treat yourself to a gear upgrade this holiday season and feel the joy of working with complete peace of mind. For festive, top-rated welding protection picks, unwrap the Arc Solutions Holiday Buying Guide.

Back to blog